These 20° Big Block Chevy Pistons are Ready to go Drag Racing | JE Pistons

The New 20° Series Big Block Chevy Pistons from JE

JE Pistons’ latest addition to our lineup of BBC pistons are designed for 20° cylinder heads and are purpose-designed and purpose-built to deliver performance and durability on the drag strip. We’ve built countless sets of custom pistons for SR20 BBC builds, so we thought why not throw our best features and techniques at a complete line of shelf parts? This way, our racers still get the custom performance they need without the longer lead times of the custom piston process.

Our 20° BBC pistons are built to serve your high horsepower build, whether you’re lining up for traditional drag racing, Grudge racing, or No Prep. Engineered, forged, and machined in-house in the USA using 2618-T6 aluminum, these BBC pistons are offered in nitrous and N/A dome configurations and cover bore sizes from 4.600″ to 4.625″. Each set of slugs feature proprietary, innovative features, including:

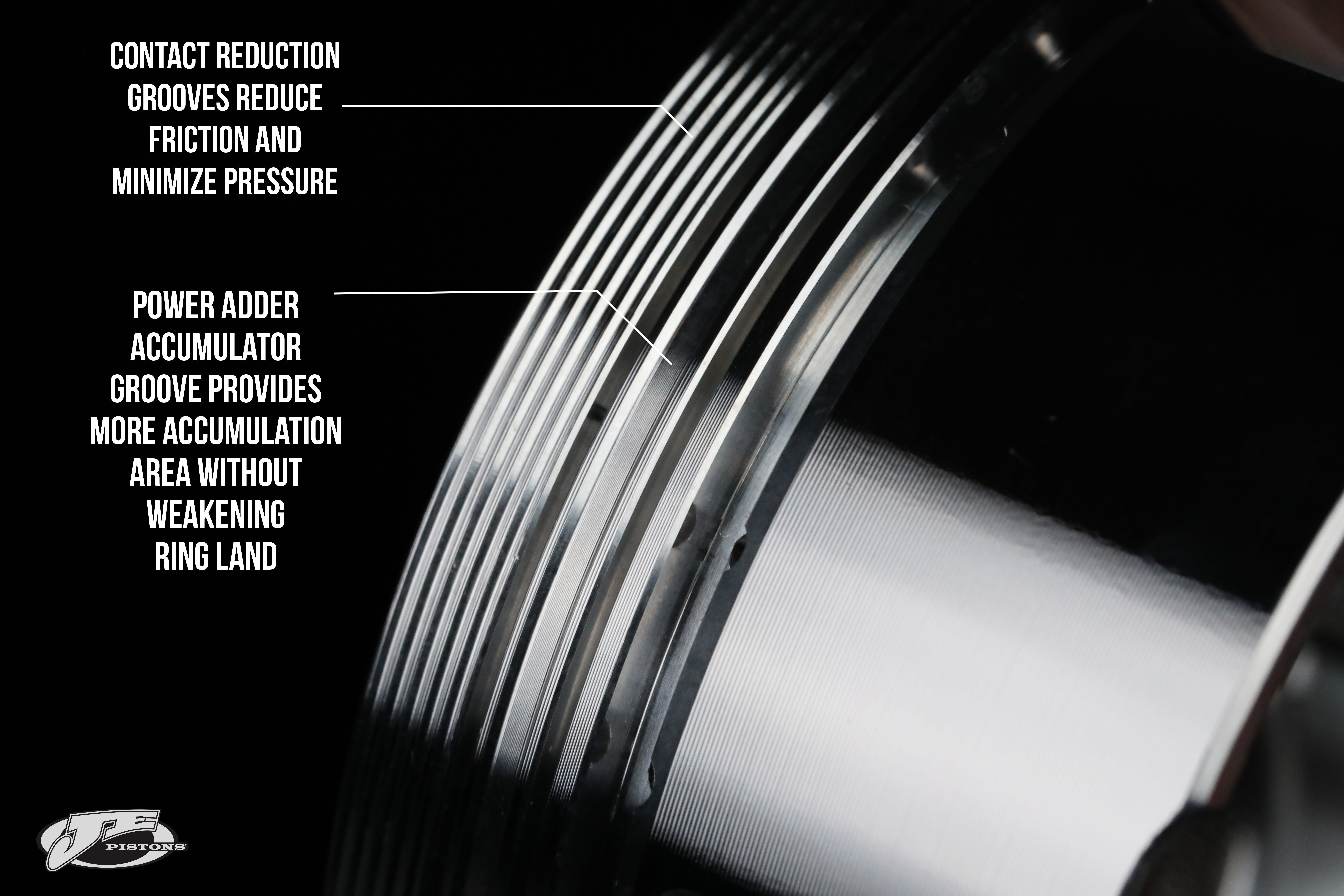

Contact reduction grooves machined into the piston above the top ring groove help minimize expansion in that area to reduce contact with the cylinder wall, reducing friction and minimizing pressure. A specially design ‘Power Adder’ accumulator groove provides more surface area than a traditional design to trap gases that make it past the top ring, helping prevent ring flutter and keeping ring seal consistent.

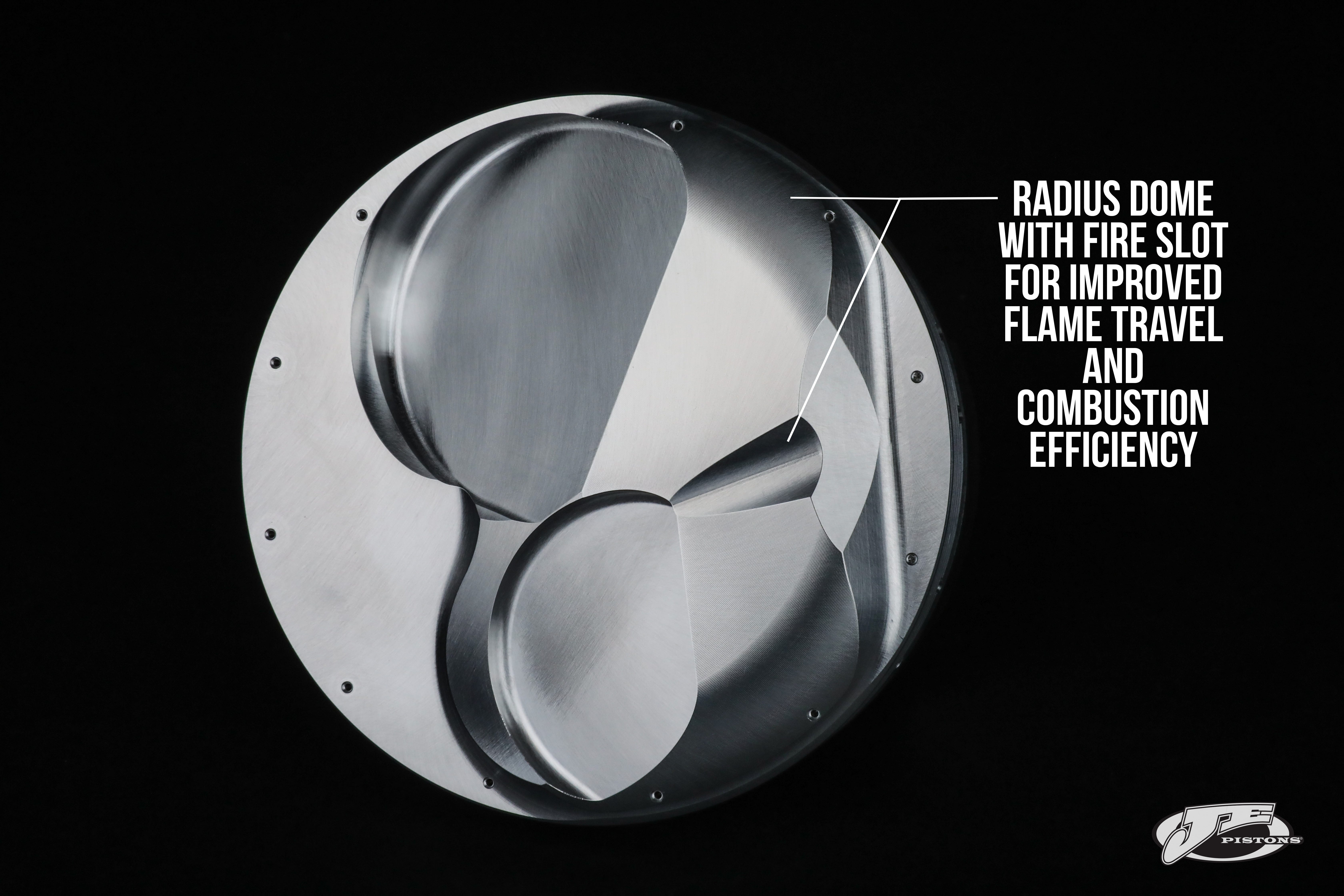

The piston dome design features smooth radius shaping and a strategically-placed fire slot to help improved flame travel and efficiency during combustion. Consistent combustion patterns help reduce hot spots, lowering chances of creating high-stress areas on the piston and maintaining durability.

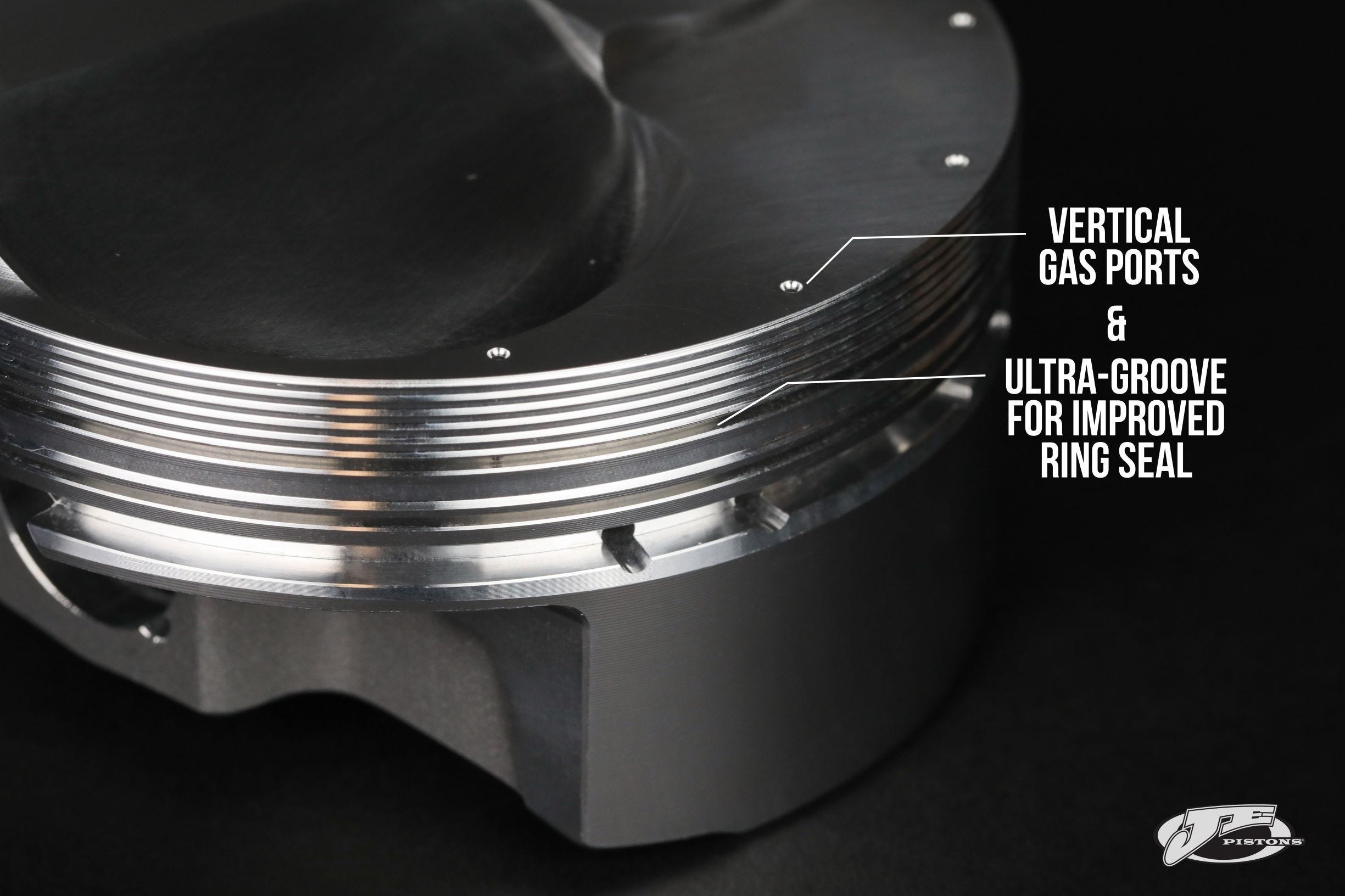

Vertical gas ports allow combustion gases to travel into the back of the top ring groove. During engine operation, these gases push the top ring out and against the cylinder wall, helping maintain consistent ring seal. Ultra-Groove is achieved through an additional ring groove machining operation that creates an incredibly flat and uniform surface for the top ring, further supporting optimal ring seal.

Want to learn more on gas porting? We dive deep into the technical details here.

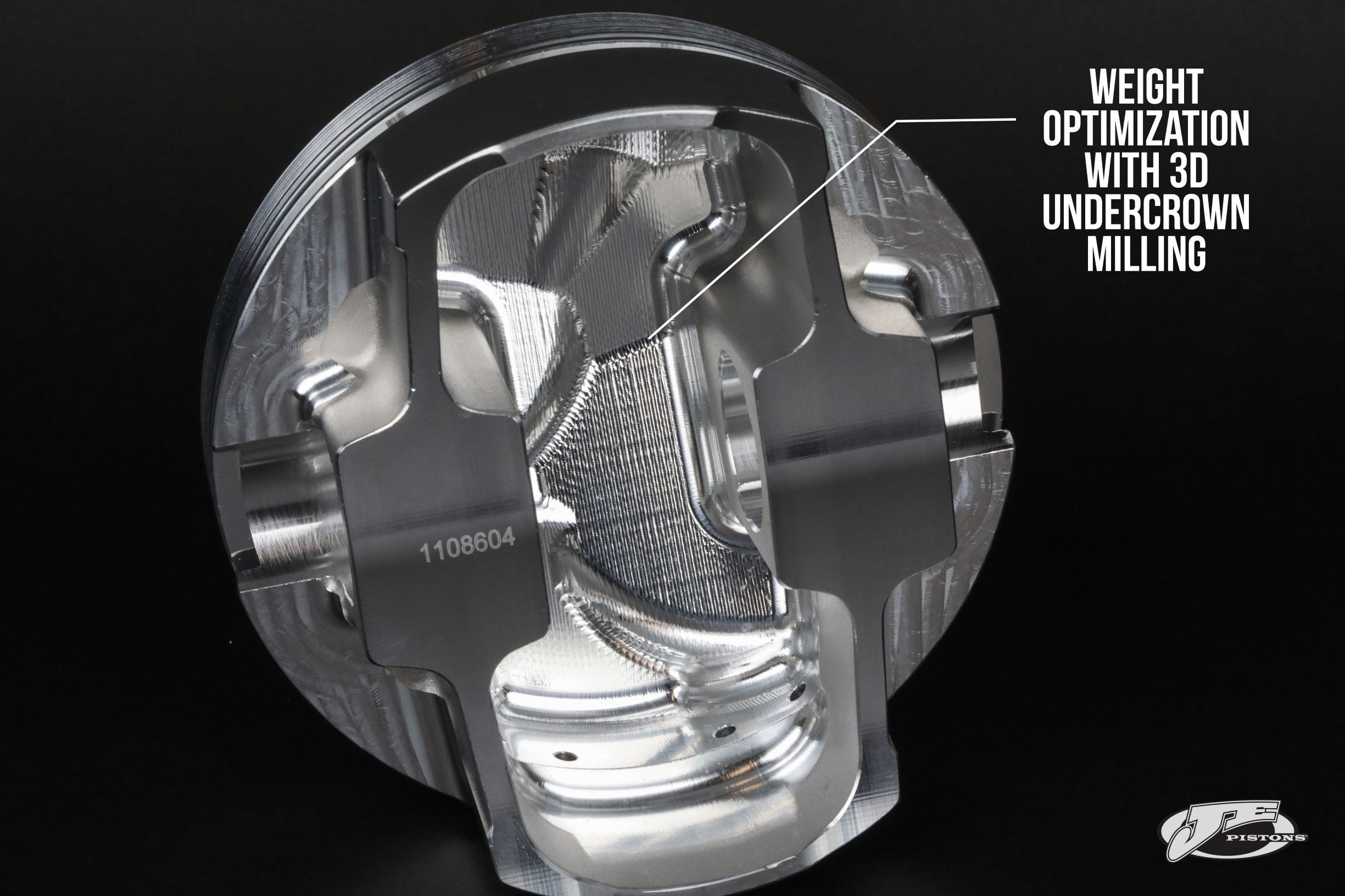

Our 3D undercrown milling operation removes unnecessary material from the undercrown of the piston, allowing the part to maintain its integrity and strength while reducing the overall weight.

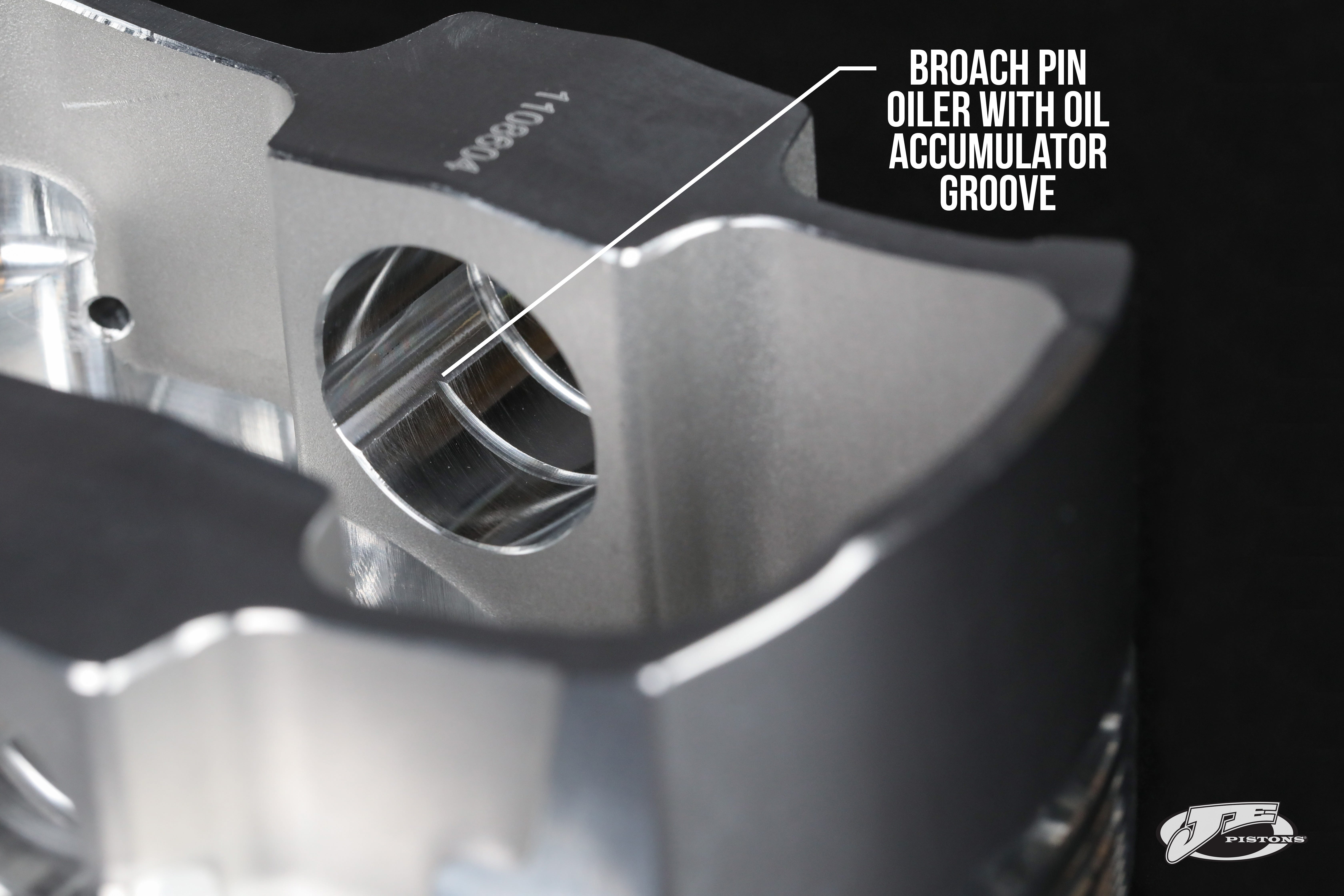

Keeping the wrist pin lubricated is critical to prevent wear and failure, especially in high-horespower NA and power adder builds. Broach pin oilers are perpendicular slots machined into the pin bore that allow oil to accumulate and maintain a film between the pin bore and pin surface. For good measure, and additional groove is machined in the pin bore parallel with the lock groove, helping guide the oil accumulated in the broach consistently across the pin bore.

Want to learn more about pin oiling? Check out our guide to different wrist pin oiling styles here.

Combined, these features help create the ultimate package for 20°-headed BBC builds, but we didn’t stop there. The valve pockets on our SR20 pistons are designed to accomodate 2.450″ intake valves, covering even more build scenarios with shelf part availability. Additionaly, these pistons are designed for a robust ring pack with .043″ steel top ring, ductile iron Napier second ring, and 3mm oil ring. After all, what good are performance pistons without performance rings to match?